Chicken feed mixing and crushing machine is suitable for farms and small poultry farm or home use to make powder animal feed. It is suitable for crushing grain materials such as corn, wheat, soybean and soybean meal. The machine is crushing and mixing at the same time. It has a high efficiency. The feed crushing and mixing machine has the two function of grinding animal feed, and mixing animail feed. Equal to two separate machines.

1.2 in 1 poultry feed crushing mixer, can save your space, save the cost, and absorb the raw materials by yourself, fully automatic feeding.

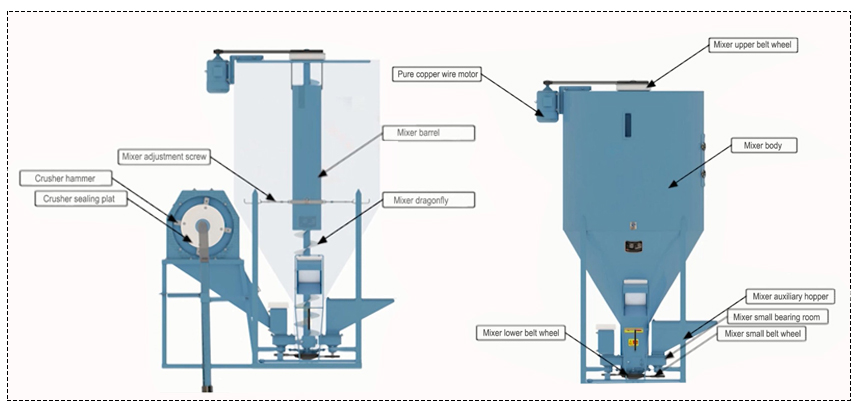

2. The crushing part is a hammer mill, which has the characteristics of automatically absorbing raw materials, the mixing part is a vertical spiral type, and the feed mixer is concentrated together, and the floor space is small and the cost performance is high.

3. Production scale from 500 kg per hour to 2000 kg per hour, suitable for small poultry farms or households to make powdered animal feed.

4. Feed crushing mixer has simple structure, reasonable process, convenient installation and simple operation.

5, the feed can be quickly crushed, mixed and stored materials, and the production efficiency is high, low power consumption

| Model | Crushing Power(kw) | Mixing Power(kw) | Capacity | Mixing time(min) |

| LM-250 | 7.5kw | 2.2kw | 250kg/batch | 10-15min/batch |

| LM-500 | 11kw | 3kw | 500kg/batch | 10-15min/batch |

| LM-1000 | 11kw | 3kw | 1000kg/batch | 10-15min/batch |

poultry feed crushing and mixing machine working, first start the mixing and stirring mechanism, then start the pulverizing lifting mechanism, then pour the material into the hopper of the feeder, and gradually open the feeding adjustment switch. At this time, the material enters the pulverizing lifting mechanism l with the airflow, in the hammer Under the impact of the sheet, the material is pulverized into particles of the required size, and then slides through the slider into the bottom of the mixing mechanism under the action of the airflow thrust and its own gravity. In this process, the airflow is guided by the return air mechanism. Under the action of the plate, it is re-introduced into the pulverizing lifting mechanism to realize the air circulation, and the material is directly passed through the air guiding plate and is lifted into the storage mechanism by the mixing and stirring mechanism. If additional concentrate is needed, the material can pass through the fine hopper. Add to the material and cycle through. After the material is crushed or reaches the maximum volume of the body, the crushing and lifting mechanism is closed first, and then the stirring is performed for 3-5 minutes to complete the feed production process.