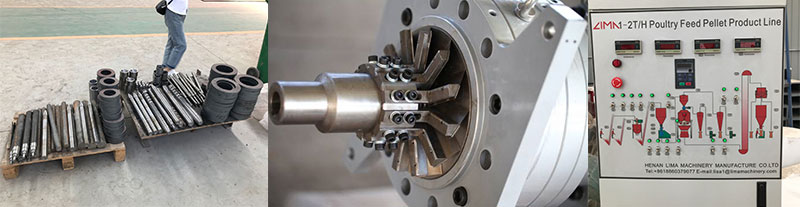

As a feed machine manufacturer, Lima Feed Machinery own experts and R & D personnel for feed equipment, mainly produce dry and wet type fish feed extruder, small mesh-belt dryer, horizontal single-shaft mixer, and some feed and agricultural equipment. Especially, the main parts of feed extruder which plays important role of floating fish feed plant is screw, it is made of carbon steel or 304 stainless steel with high strength and long service life.

The cutter of fish feed extruder is important for feed pellets of yield and shapes, it is detachable and easy to maintanance.

Adopt PLC control system, detailed introduce how to operate the main machine.

Water-drop hammer mill is the large grain crusher, used in large scale flour mill plant and feed plant, choosing suitable crusher in accordacne with clients' yield of reruipments.

FLION Machinery should send some free assemblies for clients, such as tools, clothes, gifts, etc.

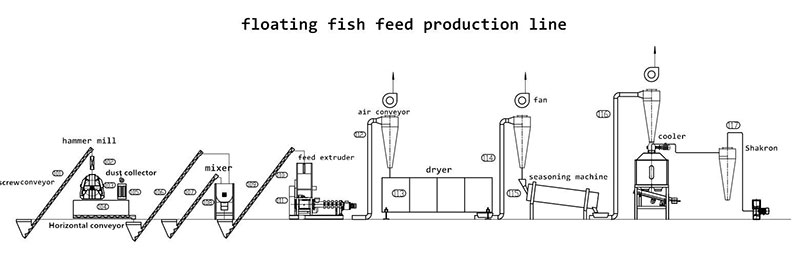

1T/H Floating Fish Feed Plant Main equipment

screw conveyor → water-drop hammer mill → horizontal screw conveyor → 2set screw conveyor → horizontal single shaft mixer → screw conveyor → fish feed extruder → dryer → Pneumatic conveying system → seasoning machine → Pneumatic conveying system → cooler → Pneumatic conveying system → package machine

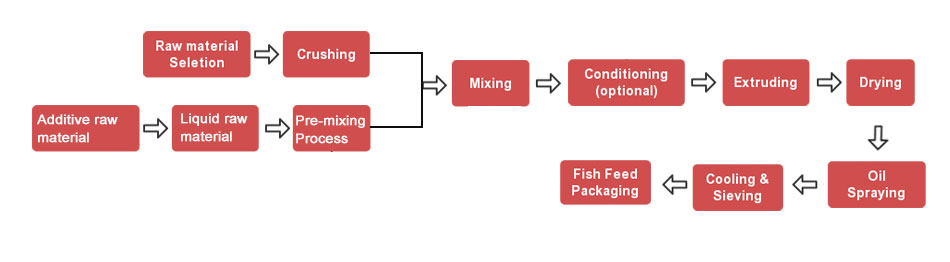

1T/H Floating Fish Feed Plant manufacturing process

| Machine Name | Description | Picture |

| Screw Conveyor | Power:2.2kw Capacity:1000KG/H-1500KG/H Application:transporting the crushed materials into mixer Quantity:4 |

|

| Water-drop hammer mill | Power:22kw Capacity:1t/h-1.5t/h Application:Used to crush grain feed (corn,soybean,etc.), rice husk, corn cob, straw pieces,etc. Quantity:1 |

|

| Pulse dust collector | Power:1.5kw Capacity:1t/h-1.5t/h Application:Dust removal, protect environment. Quantity:1 |

|

| Horizontal conveyor | Power:1.5kw Capacity:1.2t/h-1.5t/h Application:transporting the crushed materials. Quantity:1 |

|

| Mixer | Power:7.5kw Capacity:500kg/min(5-15min/time) Application:mixing crushed feed materials with vitamins and premix etc. Quantity:1 |

|

| Fish Feed Extruder machine | Power:90kw Capacity:1t/h-1.2t/h Application:Extruding fish/pet/animal feed pellets Quantity:1 |

|

| Dryer | Power:50kw Capacity:1t/h-1.5t/h Application:Drying fish/pet/animal feed pellets, easy to store Quantity:1 |

|

| Drum type oil spraying seasoning machine | Power:1.1kw Capacity:1t/h-2t/h Application:Increase the taste of fish feed and strengthen the lure Quantity:1 |

|

| Cooler | Power:4.75kw Capacity:1t/h-2t/h Application:Reduce the temperature of feed pellets Quantity:1 |

|

| Packing machine | Power:1.1KW Capacity:≤300bag/H Application:Packing the feed pellets in suitable weigh Quantity:1 |

|