.jpg)

Floating fish feed production line can process and extrude 1mm, 1.5mm, 2.0mm-13mm feed. These feed is suitable for shrimp, crab, fish, sea cucumber, turtle, loach, eel and other freshwater aquatic animals. The single-screw wet feed extruder is used in the fish and shrimp feed pellet production line, as main extruding machine. This fish feed machine improves the quality of feed pellets, reduces the loss of water-soluble vitamins in water, has a lure effect and improves palatability.

Professional engineers design different production lines for fish and shrimp feed pellets according to the needs of customers. Fish feed machine, crusher or mixer can be exchanged and matched.

Main fish feed machine technical parameters

| Model | Capacity (kg/h) |

Main Shaft power |

Feeding power (kw) |

Screw diameter (mm) |

Cutting power (kw) |

Dimension (mm) |

Weight (kg) |

| LM-40 | 40-60 | 7.5KW | 0.4 | 40 | 0.4 | 1500*1400*1250 | 350 |

| LM-50 | 80-100 | 11 KW | 0.4 | 50 | 0.4 | 1470*1100*1250 | 400 |

| LM-60 | 120-150 | 15 KW | 0.4 | 60 | 0.4 | 1470*1120*1250 | 450 |

| LM-70 | 180-200 | 18.5 KW | 0.4 | 70 | 0.75 | 1650*1400*1300 | 600 |

| LM-80 | 260-300 | 22 KW | 0.6 | 80 | 0.6 | 1800*1450*1300 | 690 |

| LM-90 | 350-400 | 37 KW | 0.6 | 90 | 0.8 | 2100*1450*1350 | 950 |

| LM-120 | 600-800 | 55 KW | 2.5 | 120 | 1.1 | 2400*1950*1600 | 1700 |

| LM-135 | 800-1000 | 75 KW | 2.5 | 135 | 1.5 | 2550*2050*13650 | 1900 |

| LM-160 | 1200-1500 | 90 KW | 3 | 160 | 2.5 | 3100*2650*1800 | 3200 |

| LM-200 | 1800-2000 | 132 KW | 4 | 195 | 2.2 | 3100*2850*1900 | 3800 |

| LM-TSE98 | 2000-3000 | 110 KW | 1.5 | 98 | 4 | 6678*1978*1150 | 4000 |

| LM-TSE128 | 3000-7000 | 220 KW | 2.2 | 128 | 5.5 | 7999*2335*1240 | 5800 |

The advantages of feed pellets produced by fish feed machine

(1) The feed produced by fish feed extruder retains a large number of beneficial live bacteria and a variety of active proteins, which can be directly consumed by shrimp, crab, fish, turtle, loach, yellow frog, etc. At the same time, it can also cultivate bait organisms, indirectly for shrimp, Crabs, fish, sea cucumbers, turtle loach, eel, etc. and provide nutrition without polluting the water quality.

(2) The feed produced by fish feed extruder can not only play a role in attracting and promoting the digestion and absorption of shrimp, crab, fish, sea cucumber, turtle, loach, eel, etc.

(3) The feed produced by fish feed extruder retains the growth of the flora, which can effectively prevent the occurrence of moss in the pond, greatly reduce the workload of shrimp, crab, fish, sea cucumber, soft-shelled turtle, loach, eel, etc., and reduce the cost of breeding medicines and diseases occur.

Why choose the fish feed production line?

1. The raw material is easy to find, just like corn meal 50%, wheat middling flour 40%, soybean meal 3%, rice flour 5%, meat 2%

2. The output pellet can floating on water within 12Hours not sink and not dispersing

3. Not sink and not dispersing keep water clearly no polluting.

4. After puffed feed pellet through high temperature will killing such as Escherichia coli and Salmonella, not only keep fish eat health food, also keep fish easy to eat and digest, make your fish growing fast.

5. Can make different size from 1mm-12mm , can feed from baby fish to big fish

6. Can using motor and diesel according to your requested

7. Easy to operate and learning .

8. We have semi-automatic and automatic from 50kg/h-8T/h output for your choice.

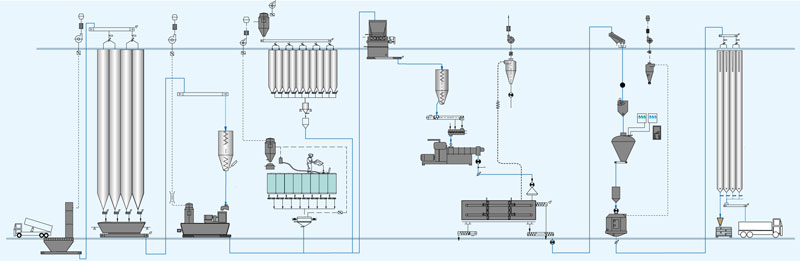

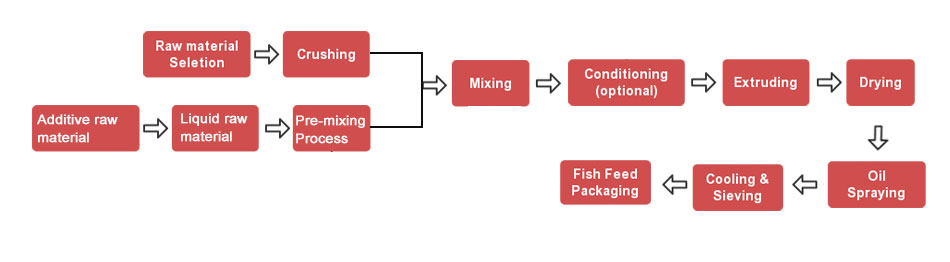

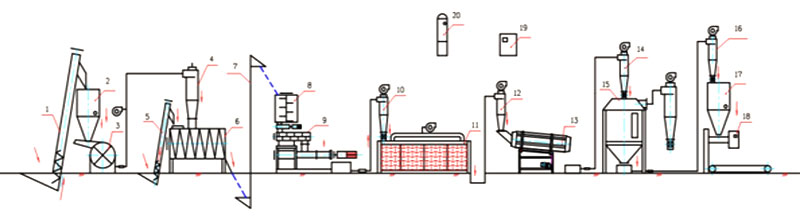

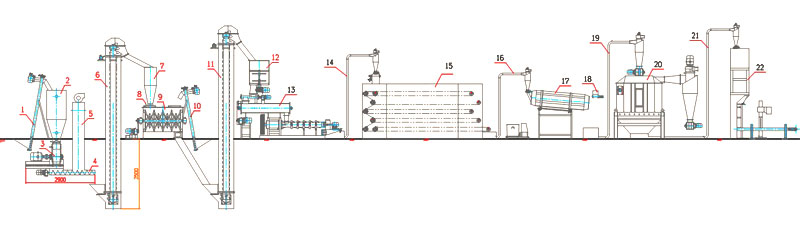

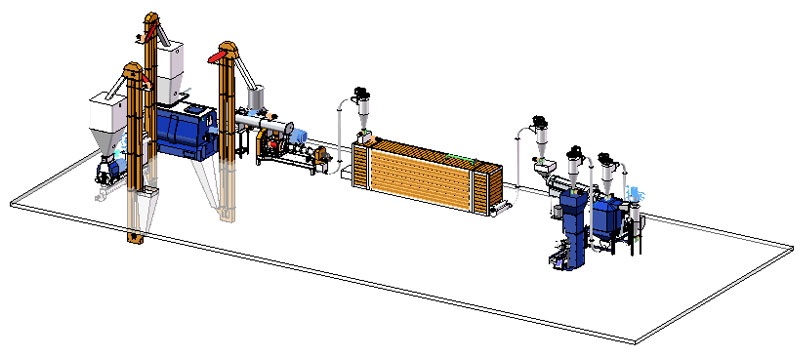

1. Process introduction:

Crushing raw materials → preparation of raw materials (corn flour, soybean meal, starch, fish meal, etc.) → mixing system → conveyor → single-screw feed extruder → conveying → drying machine (electric oven, gas fuel oil oven or steam oven) → oil injection → Single barrel seasoning system → cooling conveyor → screening → silo → packaging machine

2. the configuration of puffed fish feed processing equipment:

Crusher → Mixer → Conveyor→ Single-screw feed extruder → Conveyor → multi-layer dryer → season machine → cooler → vibration screen → packaging machine.

3. Process composition of fish feed production line:

a. Feed crushing machine: The feed crusher is mainly used to crush various feeds and various roughages. The purpose of feed crushing is to increase the surface area of the feed and adjust the particle size. To better absorb feed nutrients.

b. Feed mixing machine: mix raw materials corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour, additives, etc. with a certain proportion of water to mix thoroughly.

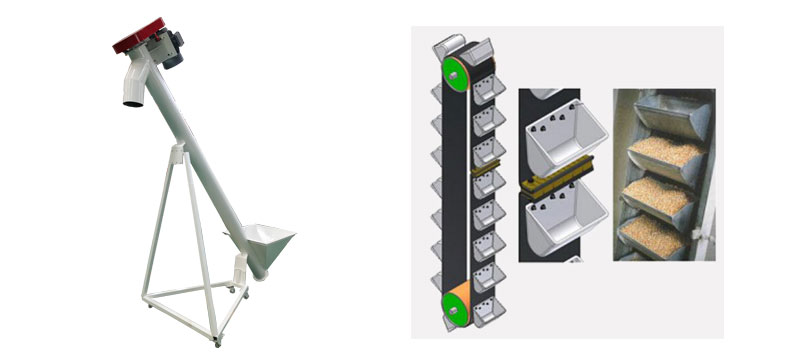

c. Feeding machine: the motor is used for power screw conveying, and the stirred raw materials are conveyed into the feeding hopper of the twin screw extruder. The feeding of this equipment is convenient and fast, saving labor and high efficiency.

d. Wet single-screw feed extruder: When the mixed raw materials are extruded under high temperature and high pressure environment and the screw, the starch structure in the raw materials changes and becomes easily absorbed nutrients. Cut the speed of the motor until the feed particles are the same size as the speed. The specific particle size and shape are obtained by changing the mold. The feed extruder adopts advanced frequency conversion speed regulation technology, which is more energy-saving and the speed control is more accurate. The current and speed of the motor can be directly seen through the inverter panel to ensure the safety of the equipment.

e. Conveyor: convey the produced feed particles to the multi-layer drying equipment.

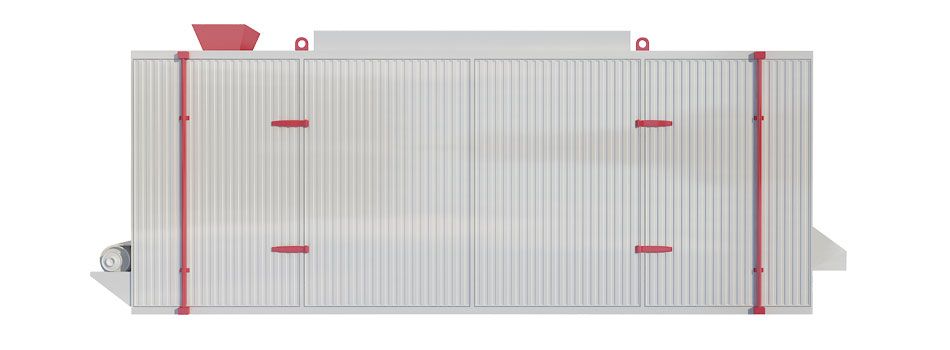

f. Drying

Fish feed pellets from pellet making machine need to lower high moisture and temperature. So mesh belt dryershould be equipped in the production line. With simple structure, it is easy to install and maintain, and ideal for fish feed pellets drying. The oven is divided into electric oven, fuel oil oven, gas oven and steam oven, the temperature is adjusted between 0-150 degrees through the control cabinet, the interior of the oven is stainless steel mesh belt, the conveyance is stable, and the failure rate is low. The feed pellets are circulated through a multi-layer S-shaped track to dry the feed pellets to a safe water content and increase the shelf life.

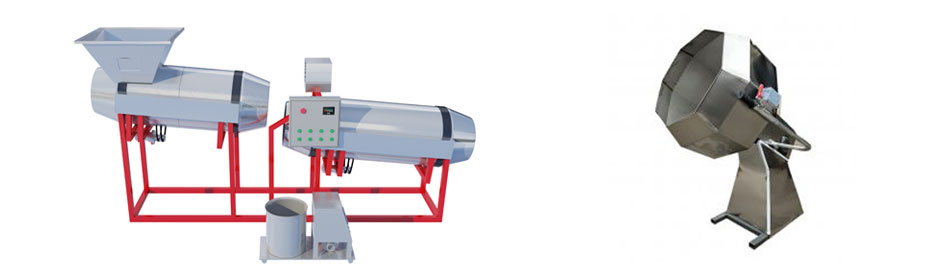

g. Spraying seasoning machine: the oil sprayer sprays oils, attractants, etc. The seasoning tube has octagonal tube, cylinder, lifting single drum and double drum seasoning line. According to the output and product nature, the grease is sprayed on the feed surface Spray minced meat and spices at the same time to sprinkle evenly. After this process,

It can remove burrs and burrs on the surface of feed pellets and make the surface of feed pellets smoother.

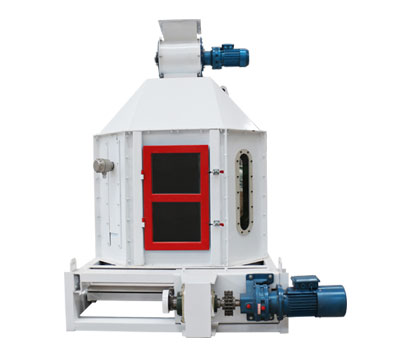

h. Cooling machine: reduce the temperature of the surface of the dried feed pellets, promote the solidification of grease, reduce the pellet temperature, and facilitate packaging.

i. Vibrating sieve: sieve out extra material and granule slag to ensure the quality and reuse of raw materials.

j. Packaging machine: manual sealing machine and automatic packaging machine can be used.

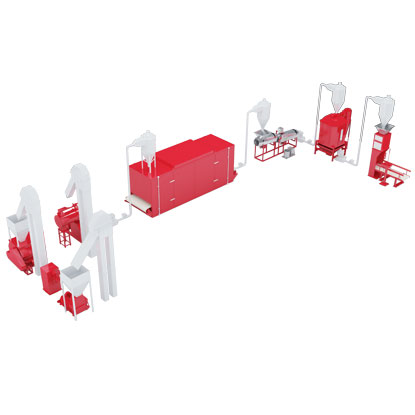

200kg-800kg floating fish feed pellet production line

1t-4t fish feed pellet line

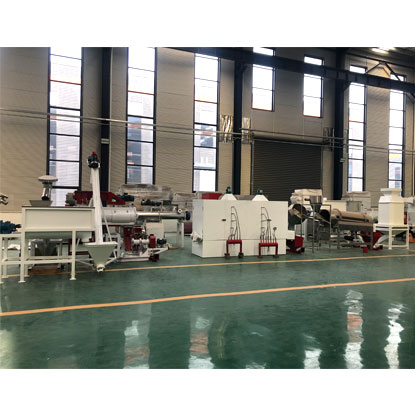

3t fish food production line

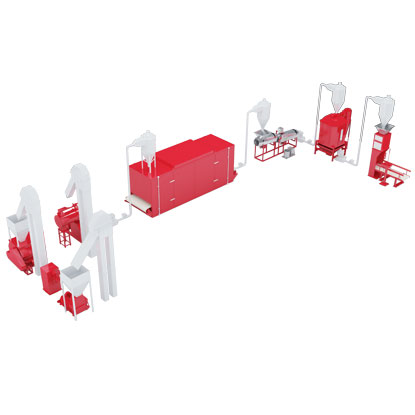

4t-20t automatic fish feed production line