There are two types of fish feed machines. This one is dry type, another type is wet type, we just talked about dry type in here. Floating fish feed machine is single screw and dry type fish feed machine which is mainly used to produce aquatic feed like for making fish feed pellet, tilapia feed pellet, catfish feed pellet, shrimp feed pellet, crab feed pellet, turtle feed pellet, goldfish feed pellet and so on. The finished pellet feed are puffed by high temperature through the heating plate in the machine. So the finished pellet can be floating on water about 24 hours because of being puffed.

Electric Fish Feed Machine

Diesel Engine Fish Feed Machine

Floating fish feed making machine has various production capacity from 30kg per hour to 500kg per hour, which is divided into small scale capacity and large capacity. Floating fish feed pellet machine has production capacity ranged 30kg/h-50kg/h, 60kg/h-80kg/h, 100kg/h-150kg/h, 180kg/h-200kg/h, 200kg/h-300kg/h, 300kg-400kg/h and so other much bigger production capacity.

This fish feed making machine is very suitable for fish farm, home use or small fish feed production factory. Other production capacity like 1000kg/h or above usually used for industrial use and commercial use like fish feed manufacturing factory.

The use of fish feed puffing machine production of fish feed is not only balanced nutrition, and the production process of maturation of materials, eliminating harmful bacteria, greatly improving the digestibility and palatability of the feed. It can effectively improve the production capacity and reduce the cost of fish feed.

If you want to make you own feed or build your own fish feed production line. Please contact us now!

| Model | Capacity (kg/h) | Main power (kw) | Feeder power (kw) | Screw Diameter (mm) | Cutter power (kw) | Machine size (mm) | Weight (kg) |

| LM40 | 30-40 | 5.5 | 0.4 | Φ40 | 0.4 | 1400*1030*1200 | 220 |

| LM40-Diesel | 30-40 | 12HP | 0.4 | Φ40 | 0.4 | 1400*1250*1200 | 320 |

| LM50 | 60-80 | 11 | 0.4 | Φ50 | 0.4 | 1470*1100*1250 | 320 |

| LM50-Diesel | 60-80 | 18HP | 0.4 | Φ50 | 0.4 | 1500*1170*1050 | 540 |

| LM60 | 100-150 | 15 | 0.4 | Φ60 | 0.4 | 1470*1100*1250 | 350 |

| LM60-Diesel | 100-150 | 25HP | 0.4 | Φ60 | 0.4 | 1570*1100*1250 | 580 |

| LM70 | 180-200 | 18.5 | 0.4 | Φ70 | 0.4 | 1650*1400*1300 | 580 |

| LM70-Diesel | 180-200 | 30HP | 0.4 | Φ70 | 0.4 | 1750*1400*1300 | 680 |

| LM80 | 200-300 | 22 | 0.6 | Φ80 | 0.6 | 1800*1450*1300 | 695 |

| LM80-Diesel | 200-300 | 35HP | 0.6 | Φ80 | 0.6 | 1900*1450*1300 | 880 |

| LM90 | 300-400 | 37 | 0.6 | Φ90 | 0.8 | 2100*1450*1350 | 950 |

| LM120 | 500 | 55 | 0.6 | Φ120 | 0.8 | 2200*1450*1350 | 1860 |

A complete fish feed production line should include the following process: Material Crushing →Material Mixing→Pellet Extruding→Pellets Drying→Oil Spraying →Pellets Cooling→Pellet Packing.

100-200KG/H Simple Fish Feed Production Line

500kg/h Fish Feed Production Line For Sale (Capacity Can Be Customized)

1.Material Crushing

In order to accelerate mixing process and increase nutritional utilization, people need to grind raw materials into powder, which always requires a crushing machine – Hammer mill crusher. In the meantime, the powder sizes of materials have great effect on feed size and quality in the pelleting process, the powder with smaller size will be much better for the pellet process.

2. Materials Mixing

The daily intake of fish is very small, hence. To ensure fish can get complete nutrition from daily feed, the feed ingredients should be mixed uniformly after grinding. It’s very important to use high mixing degree of blender because it can influence the quality of fish feed. Our production line has matched well-designed fish feed mixer for equably blending powder or particle materials with good flow ability.

3. Pellet Extruding

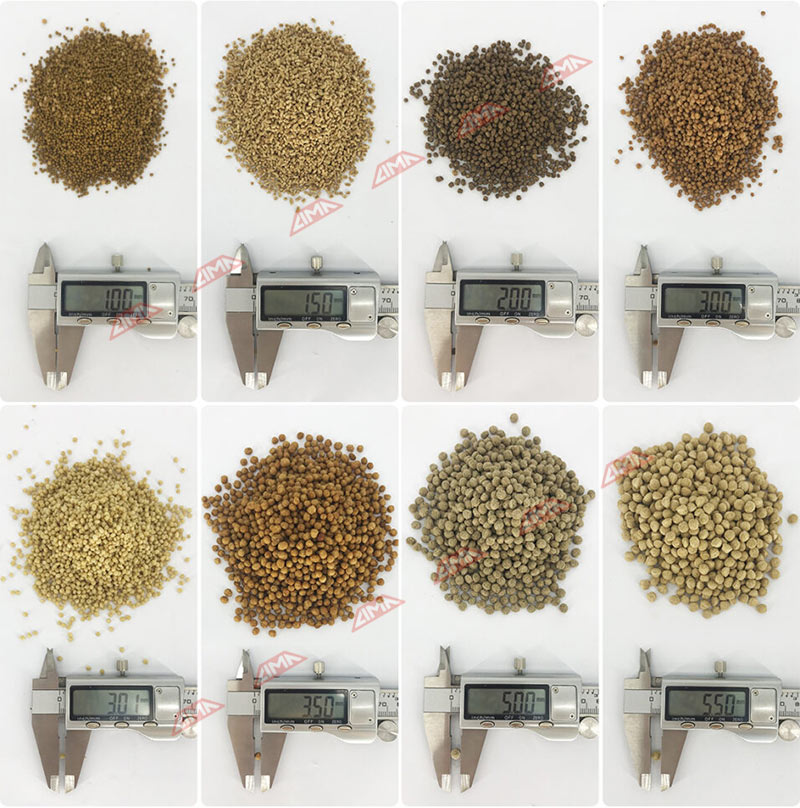

Our fish feed pellet machine is able to produce high quality feed pellets for fish and also for pets like dog and cat. Moreover, it is not hard to produce feed pellets with different diameters (usually from 0.9mm to 15mm), just changing the size of pellet mill die mold, which gives fish farmers more flexible choice according to fish type and growth situation. Pellet machine is the key equipment of whole production line ,the user can choice it according to their investment cost, production scale, and feeding characteristics and habits of different aquatic animals.

4. Pellet Drying

Produced fish feed pellets are in high temperature and high moisture content , so fish feed pellets dryer is needed to dry pellets, which can reduce pellet moisture rapidly. Feed pellet dryer is ideal equipment for pellet drying.

5. Oil Spraying

The good taste and nice smell will attractive fish for more intake, This oil sprayer machine rotates with high speed, spraying atomized oil on both surfaces of the fish feed pellets. It will produce flavoured fish feed pellet and the oil will prevent moisture absorb, Excess oil during this process is then recycled through a special filter.

6. Pellets Cooling

When the pellet temperature high, they become soft, and can easily break. We need cool feed pellets and make it hard. The cooling type adopted by most fish pellet production plants is the counter flow cooler.

7. Fish Feed Pellet Packing

Automatic weighing and packing machine can weigh and pack fish feed pellet machine in to bag ,for pellet store, transport, and sell on the market .It can also prevent feed deterioration and thus prolong its shelf life.

1. The fish feed machine is widely used for producing floating feed pellets of all kinds of aquatic animal, like tilapia, catfish, shrimps, crab etc.

2. Both floating and sinking aqua-feed pellets both can be made just by adjusting feed formulation.

3. Different molds can be chosen to make pellets with different diameters and shapes, size range is 0.9-15mm.

4. The fish feed pelletizer adopted electric heating device to improve the feed expansion rate and pellets floating time.

5. Auto-temperature control system makes the temperature controlling more precise and operation friendly.

6. High temperature and high pressure process can kill the salmonellosis and bacterial infections in materials and also makes the pellets easier to digest and absorb.

7. Advanced technology and humanized design ensures easy operation and reliable performance, high efficiency, low power consumption.

8. Dry type floating fish feed pellet machine does not need the steam boiler with cheaper price, it is better and economic for the small and medium size fish farm.

Fish Feed Pellets Manufactured By Our Fish Feed Extruder

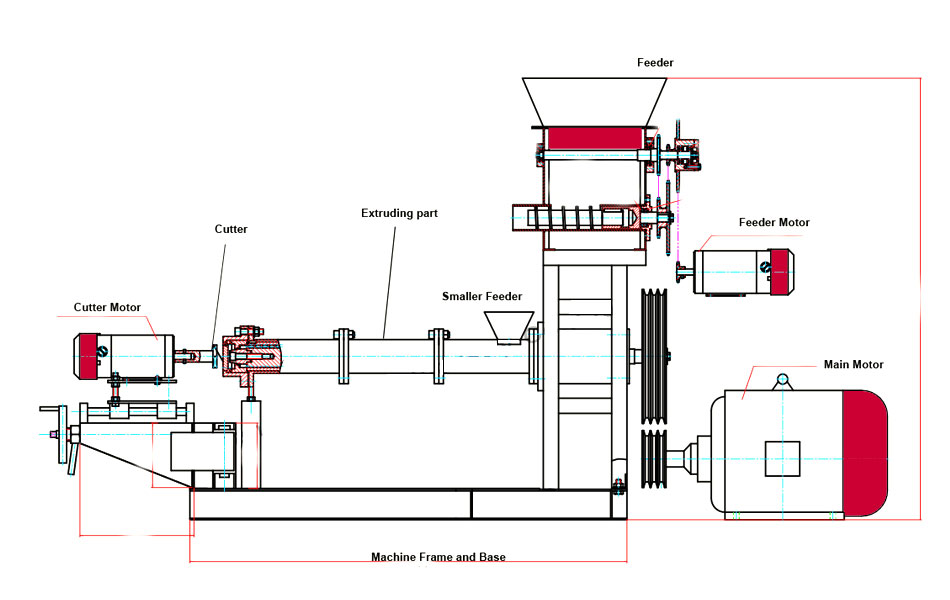

Before using the aquaculture feed pellets maker, needs to be the entire aquaculture feed pellets forming machine structure simple to understand, we first material poured into the stirring compartment, water and adding suitable, and then start the feeding motor and main motor, rotating the driving wheel to drive it, so as to drive the driven wheel is rotated, thereby bringing feeding blade rotated, so that the raw material is stirred well, then mix well, the stirring in the stirred material is poured into the extruder system, due to the effect of the protective cover, and then start the cutting electric motor, thereby driving the rolling roller is rotated, thus achieving the object of the extruded material so that the particles produced from the extruded hole, squeezed It is cut out of the material under the effect of rotation of the blade of a small particle, and finally slipping out of the machine from the discharge port.