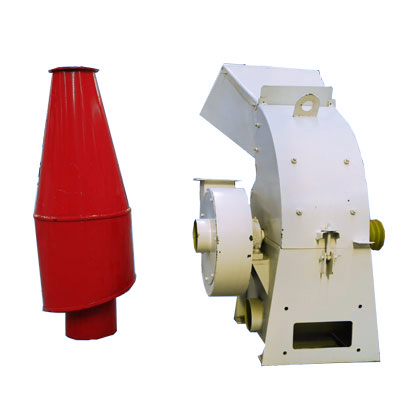

9FQ crushing machine is also named hammer mill crusher is widely used in farm, wood and feed factory, etc. The raw materials can be kinds of grain, grass, even wood chips, wood branch, stalks, carton, waster paper etc.

1.adopts the motor direct drive, high transmission efficiency,the rotor by the dynamic balance efficacy, work smoothly.

2.Can be used with the factory production of vertical agitator, advanced performance.

3.Low power consumption and high efficiency.

4.Reasonable structure, easy operation and maintenance.

5.Low noise and low dust pollution.

| Model | 9FQ-35 | 9FQ-36 | 9FQ-40 | 9FQ-42 | 9FQ-50 |

| Rotating speed | 5200r/min | 4600r/min | 3500r/min | 3200r/min | 3300r/min |

| Rotor diameter | 300mm | 300mm | 400mm | 500mm | 500mm |

| Sieve size(mm) | 380x200 | 520 x200 | 620x200 | 690x250 | 750x250 |

| Capacity | 80-200kg/h | 150-300kg/h | 200-500kg/h | 300-900kg/h | 800-1700kg/h |

| Hammer(piece) | 24 | 12 | 12 | 16 | 16 |

| Back tooth(piece) | 2 | 2 | 2 | 3 | 3 |

| Tons of electricity consumption |

≤ 11KW.h/t | ≤ 11KW.h/t | ≤ 11KW.h/t | ≤ 11KW.h/t | ≤ 11KW.h/t |

| Voltage | 220V | 380V | 380V | 380V | 380V |

| Power | 3kw | 4KW | 7.5kw | 11kw | 15kw |

| Spare parts | In and out of the hopper | ||||

| Machine size(mm) | 700x570x100 | 750*500*800 | 1100*900*1200 | 1650*820*1200 | 1800*900*1120 |

| Weight | 90kg | 170kg | 230kg | 260kg | 540kg |

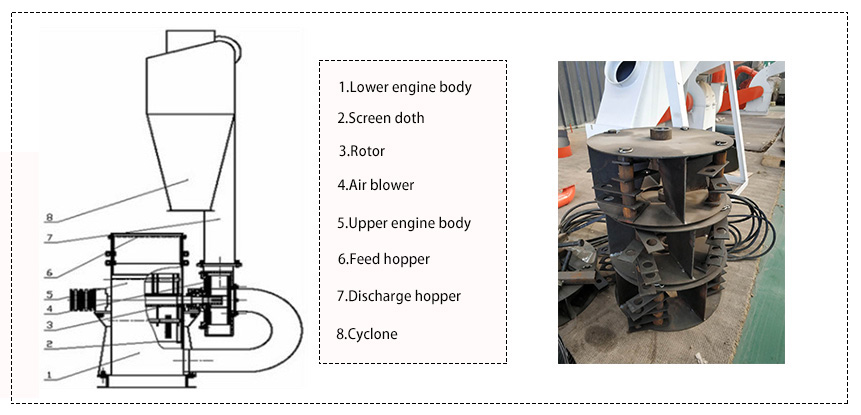

Hammer mill grinder working, the material to be processed from the hopper into the crushing chamber, by the high-speed rotation of the working parts of the fight against and rupture, while changing the direction of movement of the material, due to high-speed rotation of the working parts of the destruction of the material layer deposition, In this process, the particles are repeatedly subjected to the impact of the working parts and the body and the collision between the particles, friction, which is gradually crushed to the geometric diameter is less than the diameter of the screen in the centrifugal force and airflow under the action of crushed material Through the sieve hole into the crushing chamber from the discharge port.