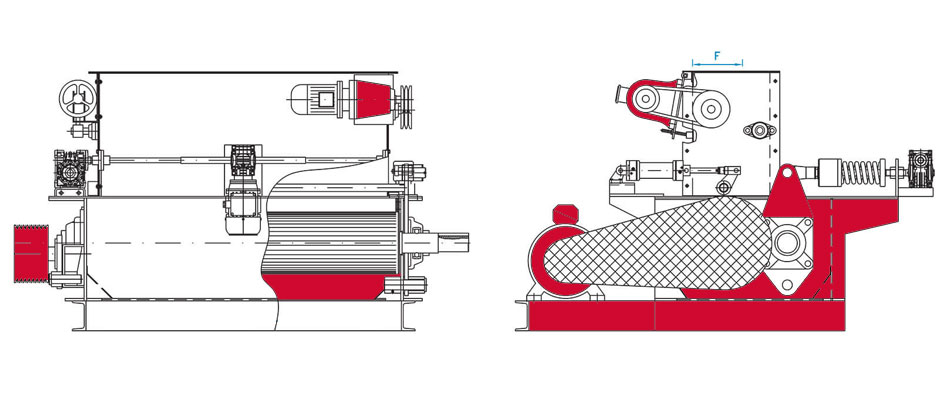

The feed pellet crusher is a special equipment to break large feed pellets into small ones. The pellets crushed by roller with common teeth are usually of 0.6-1.5mm; and crushed by roller with fine teeth are of 1-2.5mm. Pellet feed crumbler can be divided into double-roll and three-roll crushers for choice according to different types of feed pellets. According to survey, these animal feed the crushing pellets better than large pellet.

◆Compact structure, uniform crushing performance, convenient and efficient crushing size adjustment.

◆The rollers have differential rotate speed, the feed pellets are squeezed, cut and teared among the rollers, then get the ideal crushing effect.

◆Special feeding hopper ensures consistent material feeding.

◆The crusher is equipped with bypass device, which can lead the flowing of the pellets that no need to be crushed.

◆Adopt V-belt drive, stable transmission, low noise, easy operation.

◆The Y160M-4 model crusher adopts special roll spacing adjusting device that make the adjustment easy and reliable.

◆The three-roll feed pellet crusher has more continuous and stable feeding effect, and more uniform crushing result. Also its yield is improved.

| Model | Capacity | Power |

| SSLG15*80 | 1-3t/h | 5.5kw |

| SSLG15*100 | 2-6t/h | 5.5kw |

| SSLG15*150 | 3-8t/h | 11kw |

| SSLG15*170 | 5-10t/h | 15kw |

During operation, the motor is driven by a V-belt pulley and a gear, and the two rollers are rotated in opposite directions to crush the material. The roll gap can be properly withdrawn within the specified range to control the size of the discharge.

The feed hopper level is maintained at a certain height, and under the action of the gravity of the pellet feed, the pellet feed is forcibly fed between two oppositely moving rollers. At the same time, when the roller rotates, the material is pulled by the friction of the material by the roller. Under the joint action of gravity and clamping force, the material is squeezed into the roller, the roller has the roller tooth, and the pellet feed between the two rollers is squeezed. It is broken into small particles by scraping and peeling.