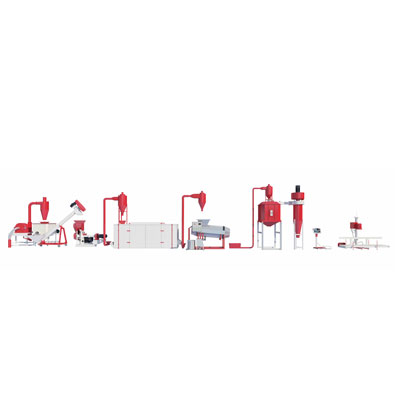

Floating fish feed production line is a full complete and automatic fish feed production plant. The complete floating fish feed production line includes fish feed extruder, fish feed crusher, fish feed mixer, fish feed dryer and other necessary equipment.

100-200Kg/H Simple Fish Feed Making Plant For Fish Farm

500kg/h Fish Feed Production Line For Sale (Capacity Can Be Customized)

4T/H Fish Feed Production Line for Sale

The floating fish feed plant can process corn, soybean, wheat, grains, protein, fish meal, bone meal and other raw materials into pellets, and finally manufacturing granules with different shapes, unique flavors, rich nutrition and fine texture, which are widely used in production goldfish feed, tropical fish feed, catfish feed, shrimp feed, turtle feed and other aquatic feed.

This floating fish feed manufacturing plant is the best choice for large and medium feed factories and farms. This fish feed making plant has different output for customers to choose from small to large. There are 100-200kg/h, 300-500 kg/h, 1000kg/h, 2000kg/h etc. on the production capacity.

Floating and Sinking Fish Feed Pellets are Made By Lima Feed Machinery

Raw material crushing → mixing materials → extruding process → pellets drying → oil spraying process → pellets cooling→ pellet packing

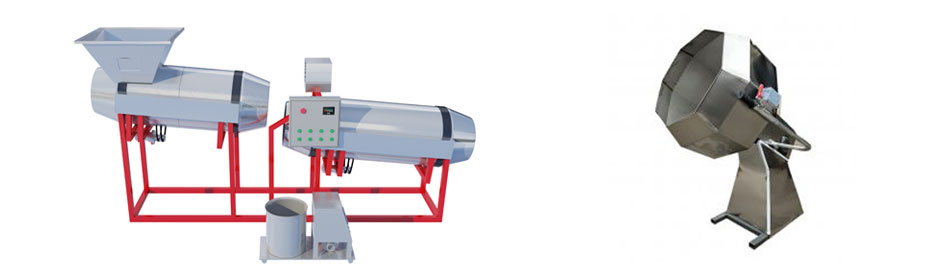

1.Crushing

Raw materials are crushed by the fish feed crusher. The particle size directly effects the efficiency of pellet making. Once feeding into the crushing chamber, materials are smashed under the high-speed rotation of hammers. With the high pressure and rapid-moving of airflow, the smashed raw materials are further reduced into particle size or very small pieces for further processing. Therefore fish feed hammer mill is suitable for fish feed pellet grinding in the production line.

Lima has five type feed crushing machine, ② and ③ is crusher and mixer application: crushing and mixing raw materials; ①④⑤ crushing machine just crush raw materials. ④ is suitable for medium and large feed production line.

2.Mixing

Powdery feed materials need to be mixed thoroughly in the mixer to ensure a high-quality of nutritional feed. We provide feed mixer with a single-shaft and twin-ribbon. It reinforces convection, shearing, and mixing effects and is an essential parts of the whole line.

Three types feed mixer machine, ① is flour mixer machine only used in small fish farms with capacity 50kg/h or less; ② is single-shaft mixing machine which is suitable for medium and small feed pellet mill plant, the capacity is 100kg/h-150kg/h; ③ is double-shaft mixer used for medium and large farms for fish feed pellets, rabbit feed pellets and pig feed pellets, etc.

3. Extruding

After mixing, feed pellet extruder will compress feed powder into sized pellets. Dry type fish feed extruder is the significant equipment with reliable performance, easy operation and cheap price, which is economic for small and medium scale production. Therefore dry type feed pellet making machine are recommend in the feed pellet plant.

Two types fish feed machine, ① is electric fish feed extruder machine adopting famous siemens motors, using power to extruding feed pellets; ② is diesel engine fish feed machine adopting motors and diesel engine can reduce the electricity. The two types fish feed processing machine is designed in capacity of 50kg/h to 500kg/h.

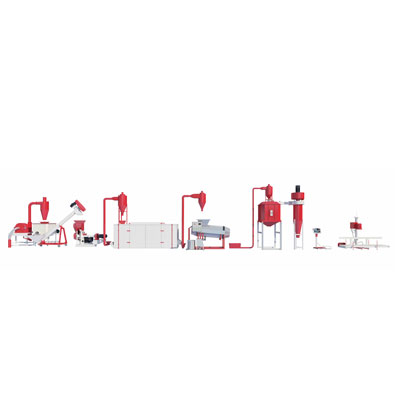

4. Drying

Fish feed pellets from pellet making machine need to lower high moisture and temperature. So mesh belt dryershould be equipped in the production line. With simple structure, it is easy to install and maintain, and ideal for fish feed pellets drying.

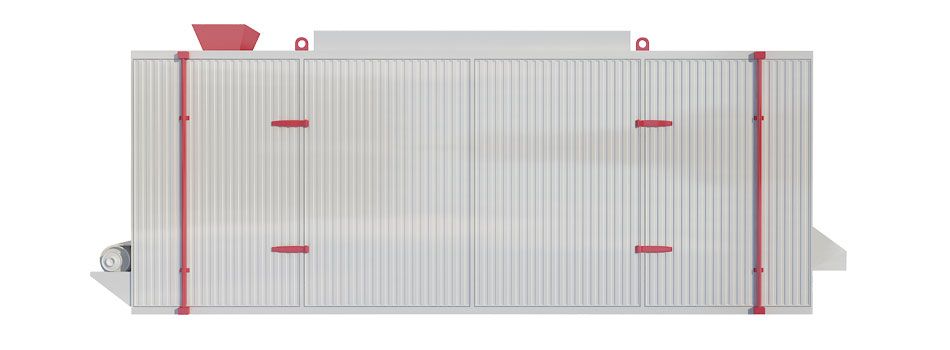

5. Oil Spraying Process

For acquiring better smell and taste, the oil spraying machine can be used to spraying oil to the surface of fish feed pellets coming out of the dryer. It sprays atomized oil with high speed on the up and down surface of pellets, and the excessive oil can be recycled through filter.

6. Pellet Cooling

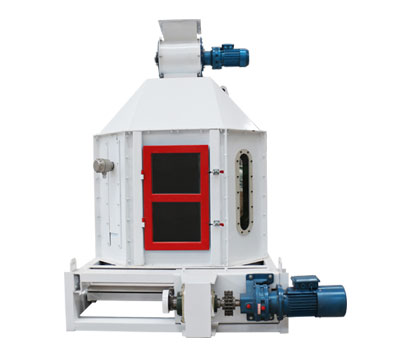

Hot pellets are soft and easily broken, which can result in a high percentage of fines. By cooling pellets can be harden. Counter flow cooler is cooling type that commonly used in pellet industry currently with the direction of the air and product of pellets in opposing directions.

7.Pellet packaging

The fish feed pellets are packaged in bags for further transporting and storage. Here you can opt pellet packing machine which is suitable for weighing and bagging pellets. Using packaging machine can increase productivity, reduce labor intensity and satisfy the needs of large-scale production and meet hygiene requirements.

1. New technology, low energy consumption.

2. The modular structure is convenient for assembly and disassembly, facilitating the shipment and installation.

3. PLC controlled, alarm device is available. Easy to operate and maintenance.

4. Final pellet shapes and sizes can be various by changing the mould. For fish and shrimp feed pellet, the floating time in water can be adjusted by the extrusion degree adjustment.

5. Processing is processed at high temperature instantaneous process, greatly reducing the decomposition of nutrients in feed, at the same time improve the protein (through the degeneration of protein) and starch (through starch paste) digestibility, to improve the palatability of the product.

6. High temperature kills some bacteria, which can improve the nutrition of feed pellets and improve the immunity of fishes

7. In order to ensure the quality and the capacity, there is the special pressure-increased device. Besides, the electric heating device improve the feed expansion rate.