Diesel Engine Fish Feed Machine is widely used for producing variety materials into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc. The final products have unique shape and good taste, high nutrition and smooth textures.

Diesel Engine Fish Feed Machine

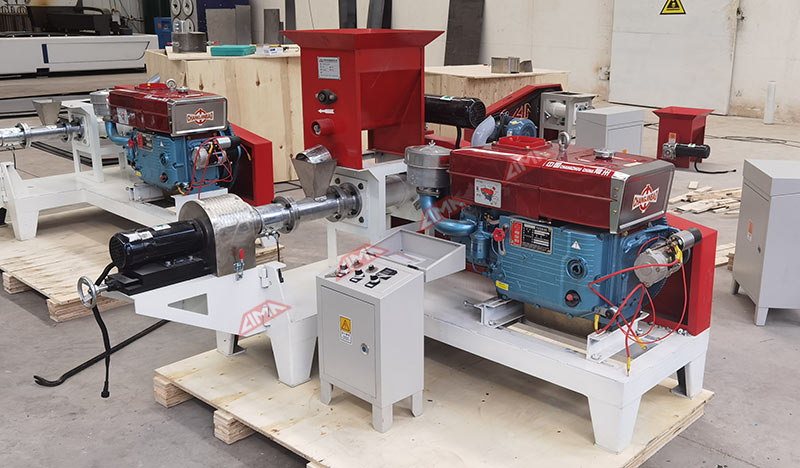

Shipment of Fish Feed Extruder

For feeds of fish and shrimp, the floating time in water can be adjusted by the extrusion degree adjustment. This floating fish feed machine is an ideal for small and medium fish farm holders or feed processing plant.

Floating and Sinking Fish Feed Pellets

| Model | Horse Power | Feeding Power | Cutting power | Capacity | Weight | Machine size(mm) |

| LM-40 | 12HP | 0.4KW | 0.4KW | 40-60kg/h | 360kg | 1400*1250*1200 |

| LM-50 | 18HP | 0.4KW | 0.4KW | 80-100kg/h | 540kg | 1660*1170*1050 |

| LM-60 | 25HP | 0.4KW | 0.4KW | 100-150kg/h | 590kg | 1470*1120*1250 |

| LM-70 | 30HP | 0.4KW | 0.4KW | 180-200kg/h | 740kg | 2050*1450*1300 |

| LM-80 | 35HP | 0.6KW | 0.6KW | 200-300kg/h | 850kg | 2150*1500*1300 |

| LM-90 | 50HP | 0.6KW | 0.8KW | 300-400kg/h | 1200kg | 2200*2000*1350 |

1. Tempering: After entering the extruder, the material should be tempered first. It is similar to the tempering process of the feed pellet mill, which is both humidified and heated to the material. The purpose of the quenching and tempering is to increase the heat and humidity of the material so as to facilitate the rapid ripening of the material during the subsequent extrusion.

2. Extruding: After tempering, material get into the screw conveyor extrusion cavity, the shape of the extrusion chamber is gradually smaller along the direction of the material. The pressure of the material is increasing during the movement, while the material in the screw conveyor extrusion cavity accompanied by strong shear, kneading and friction, the temperature of the material increased sharply.

3. Swelling: When the material reaches the outlet of the screw conveyor extrusion cavity, the pressure is the largest. After squeezing out the extrusion chamber, the pressure suddenly disappears, and at the same time, the heat and moisture lose quickly, which makes the volume of the material increase rapidly and expand.

4. Cutting: The extruded material is cut into required size when it is accumulated to a certain length.

1. No need to use electricity, the granulation work can be done anywhere.

2. It solves the problem that the electricity is inconvenient, and the three-phase power is not used, but the output is required.

3. A variety of die plates with 0.9-15mm aperture, which can extrude more than 30 kinds of common feed pellets.

4. It is used in the production of floating fish feed, suitable for small, medium family production, and large professional feed processing plant.

5. The produced feed is suitable for cat, dog, pig, bird, fish, shrimp, and other aquatic animals.

6. High temperature and high pressure in production engineering can kill common pathogenic microbes and parasites.