Wet-Process Extrusion Puffing Machine can make it possible to process a variety of fish feed ingredients, such as soybean, corn, rice, peas and raw materials with high water content. In addition to those benthonic animals, most aquaculture species can ingest floating extruded fish feed very well, not only for the famous-special fish species (like aquarium fish), but also for conventional cultivation (like grass crap, crucian, catfish, tilapia and so on).

wet type fish feed extruder machine is widely applied to produce floating fish feed pellets for fish farm, aquaculture and even poultry farms, such as pond fish farming, culturing fish in rice field, running water fish culture, cage culture, and especially for fish farm with lower breeding density, extruded floating feed has much more superiority than other fish feed.

Machine - features

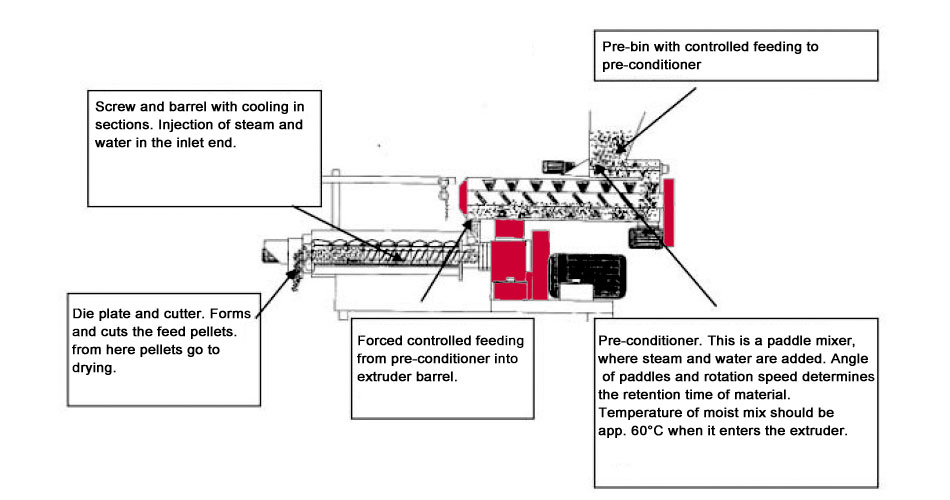

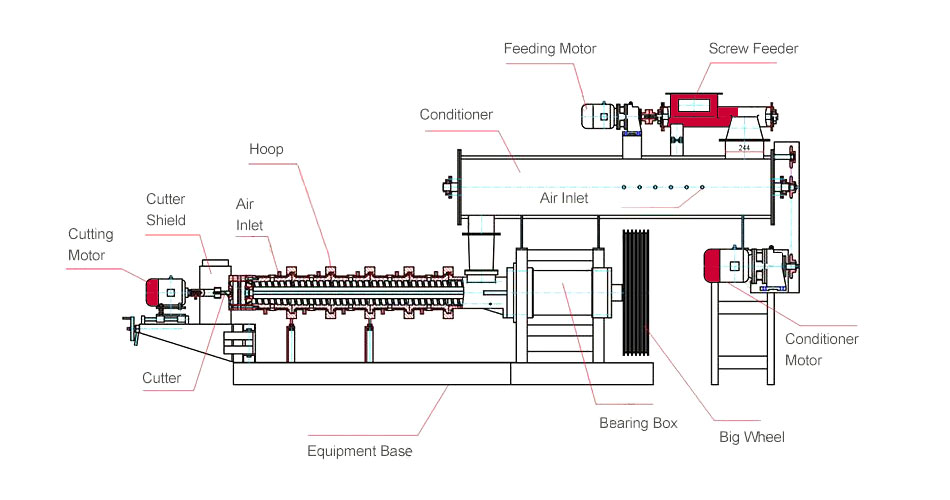

1. Drive the cutter with a variable frequency motor to control the length of the feed pellets

2. Screw sleeve adopts jacketed construction, which can be injected in with hot steam or cooling water, thus the extruding temperature can be controlled effectively.

3. The conditioner can make the materials have fully gelatinization of starch by a combination of hot steam and mechanical shear/mixing. The materials may remain in the conditioner for a time over 180s.

Raw Materials - features

1. With different parameters and feed formulation, fish farmers and feed plants can make floating, sinking and slow-sinking feed with high quality and nutrition so as to adapt for diverse ingestion requirements of various aquatic animals.

2. High temperature is to kill the germ

3. longer and easier storage period,

4. floating, sinking and slow sinking types, also can satisfy different demands of aquatic animals with various ingestion habits

| Model | Capacity (kg/h) |

Main Shaft power |

Feeding power (kw) |

Screw diameter (mm) |

Cutting power (kw) |

Dimension (mm) |

Weight (kg) |

| FPH60 | 180-200 | 15 KW | 0.4 | 60 | 0.4 | 1780×1250×1300 | 480 |

| FPH70 | 250-300 | 18.5 KW | 0.6 | 70 | 0.6 | 2460×1550×1740 | 940 |

| FPH80 | 350-400 | 22 KW | 1.1 | 80 | 0.75 | 2650×1450×1750 | 1000 |

| FPH90 | 500-600 | 37 KW | 1.1 | 90 | 1.1 | 2600×2100×1900 | 2000 |

| FPH120 | 700-800 | 55 KW | 1.1 | 120 | 1.5 | 3200×1950×1900 | 2200 |

| FPH135 | 1000-1200 | 75 KW | 1.5 | 135 | 2.2 | 3570×1980×1800 | 2500 |

| FPH160 | 1800-2000 | 90 KW | 2.2 | 160 | 2.2 | 6600×2800×2330 | 3800 |

| FPH200 | 3000-4000 | 132 KW | 2.2 | 200 | 3.0 | 6600×2900×2350 | 4500 |

wet extrusion to produce feed, extrusion processing means that in the environment of high temperature(110-200°C), high pressure(25-100kg/cm2) and high water content(10%-20%, even 30%), fish feed stuffs mixture, through heating tempering, deep mixing and particles formation, would puff and afterwards shape into extruded feed when out of fish feed extruder machine. The wet type fish feed machine needs to add water or steam into the machine to increase the moisture to 20 percent, or more than 30 percent during the process. It increases the temperature of the materials by steaming.

floating extruded feed pellets are both produced through modulator for heating and modulation, via continuous mixing process to fish feed raw materials after entering extruder machine, heating up, pressurizing, ripening, extruding and then puffing and granulating.